Challenges

ERIKS' Botlek facility specializes in the manufacture and distribution of flat gaskets. In recent years, operations from various locations have been concentrated in the Botlek. The transfer from Alkmaar at the end of 2022 is the most recent. In 2023, the transfer from Antwerp port would complete the consolidation.

The introduction of SAP-WM in March 2023 to bring logistics to a higher level was a preparatory step for this.

As a result of these changes, performance of the site had dropped sharply and ERIKS' reputation among its customers had come under pressure. The last straw was that the Operations Manager was leaving the company, and no experienced manager was available at short notice.

Task of the interim manager was:

- Reduce the order lead time from 6 weeks to less than 3 weeks

- Get the Logistics performance from below 55% to above 80%.

- Putting the various warehouses (warehouse and materials) in order.

- Preparing the site to absorb the trade and production volume from Belgium

- Investigating the need for limited shifts to achieve the required capacity

- Recruiting and training the additional personnel needed

- Bringing calm and confidence back to the Botlek team

Approach

The most acute challenge was reducing lead time. After a brief analysis, it turned out that the realized capacity was much higher than the capacity offered in the planning. As a result, all orders were pushed into the further future. By bringing the offered capacity from 60% to 85% of the realized capacity, a shorter lead time was immediately offered to sales. This immediately reduced the number of rush orders. The remaining 15% was reserved for rush orders and, if there were none, for clearing backlogs.

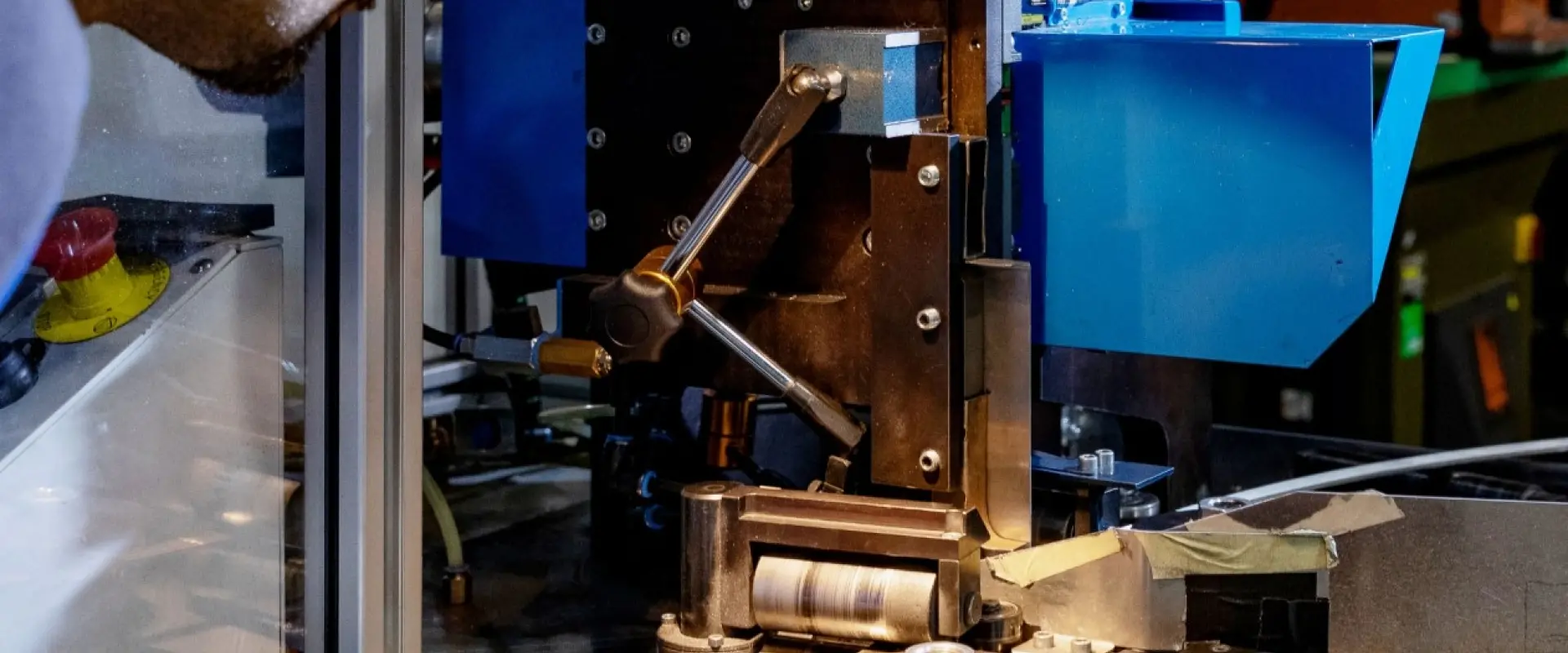

In addition, full efforts were made to run all bottleneck machines to the maximum in order to eliminate the backlog. This involved a focused lean initiative.

Due to the hasty introduction of SAP-WM in combination with the improperly equipped warehouse, inventory reliability had gone down. This had a negative effect on logistics performance. By taking a consistent and methodical approach to getting the warehouse and master data in order, there were fewer misses. The logistics team also became more and more proficient in SAP over time which certainly contributed to the improvement.

In a detailed analysis of historical production data from Belgium and Botlek, an analysis of the required capacity was made, and it was concluded that some machines from Belgium could be better transferred that only a very limited shift shift was needed. This analysis was used for the OR application and implemented.

Prior to the relocation of the Belgian Portfolio, the plant and logistics were prepared to house the machines and racking equipment.

Partly because of the preparation by a multi-functional team, the transition went smoothly and, except for a single incident, without negative effects on the market.

Results

- The order lead time has been reduced within the target of 3 weeks. Production is up to two weeks ahead, which has created even more capacity for speed orders.

- Logistics performance has been brought from 55% to just over 90% in the period May 23 to Sep 23. It dropped back a bit to 80% during the production move and has since returned to 83% and rising.